COLD FOIL

• Strengthen customer's fidelity.

• Innovative way to find new customers.

• Packaging with high communicative impact and ecologically guaranteed.

• The wide characteristic of cold foil allow to product designer new creative and spectacular ideas with low additional manufacturing costs.

• Screen lamination, but also full screen coverage, with high chromatic effects.

• Normal offset process, easy and immediate.

• No need of expensive hot foil dies; only a normal lithographic plate is required; no energy consumption.

• No foil waste in make-ready and possibility to apply again the unused parts of the foil.

• UV or traditional ink, coating and adhesive.

• To be installed on new and existing printing presses of any manufacturer like Heidelberg Speedmaster CD, CX and XL; manroland 700 and 900; KBA Rapida 106, 145, 165; Mitsubishi, Komori...

• The biggest installaton in the world on a KBA-Planeta Rapida 162-6+LX.

• Works with coated paper and cardboard from 80gr/sm and always with final varnishing.

The Foil Stamping Machine in Round-Flat Technology – for Highest Quality Requirements

| RF 82 | RF90 | |

Output per hour |

up to 4’000 sheets |

up to 4’000 sheets |

Sheet size max. |

570 x 820 mm |

640 x 900 m |

Sheet size min. |

210 x 280 mm |

290 x 450 mm |

Sheet thickness max. |

0,75 mm |

0,75 mm |

Stamping format max. |

550 x 800 mm |

620 x 880 mm |

Gripper margin |

8 – 10 mm |

8 – 10 mm |

Diameter of foil roll max. |

125 mm |

150 mm |

Distance between foil roll min. |

2 mm |

2 mm |

Feed rollers and programs |

1 – 3 |

1 – 3 |

Cylinder diameter |

540 mm |

540 mm |

Packing thickness |

1,5 mm |

1,5 mm |

Heating zones |

3 |

3 |

Heigth-adjustable form bed, adjustment range |

-0,3 to +0,3 mm |

-0,3 to +0,3 mm |

Stamping die height, standard |

7 mm |

7 mm |

Pile height, feeder |

350 mm |

340 mm |

Pile height, delivery |

510 mm |

540 mm |

Nominal output, drive |

8 kW |

8 kW |

Nominal output, heating and foil unit |

18 kW |

18 kW |

Nominal frequency |

50/60 Hz |

50/60 Hz |

Machine length |

4.000 mm |

4.300 mm |

Machine width |

2.600 mm |

3.400 mm |

Machine height |

1.750 mm |

1.750 mm |

Machine weight (without pile) |

5.500 kg |

6.800 kg |

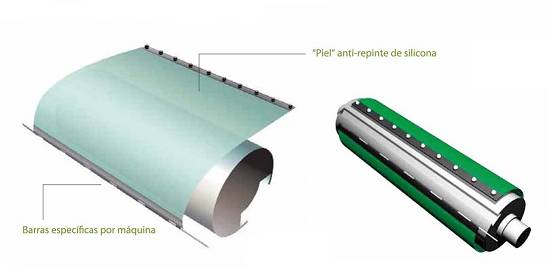

GREEN FROG

The intelligent solution of anti-marking!

Green Frog Anti-marking Jackerts are available for most Heidelberg press models (GTO 46, GTO 52, SM 52, MO, SM 74, SX 52, SX 74, SM 102) as well for Ryobi etc. You utilise the original manufacturers clamping systems on the transfer and delivery positions.

They utilize specially formulated solvent resistant elastic materials, which allow for for quick and easy installation.

The patented silicone glass bead technology incorporates a solvent resistant backing. This reduces problems with inks and has excellent recovery under most intense stresses. The surface material is a high performance anti-marking film that provides long life and the lowest maintenance. Uniform diameter, silicone coated microscopic glass beads are used in a dense matrix that greatly enhances the ink repelling properties. The manufacturing process provides an ink repellent surface that helps eliminate sheet marking and makes cleaning easier when carried out on a regular basis.